Your Manufacturing Partner for Every Stage

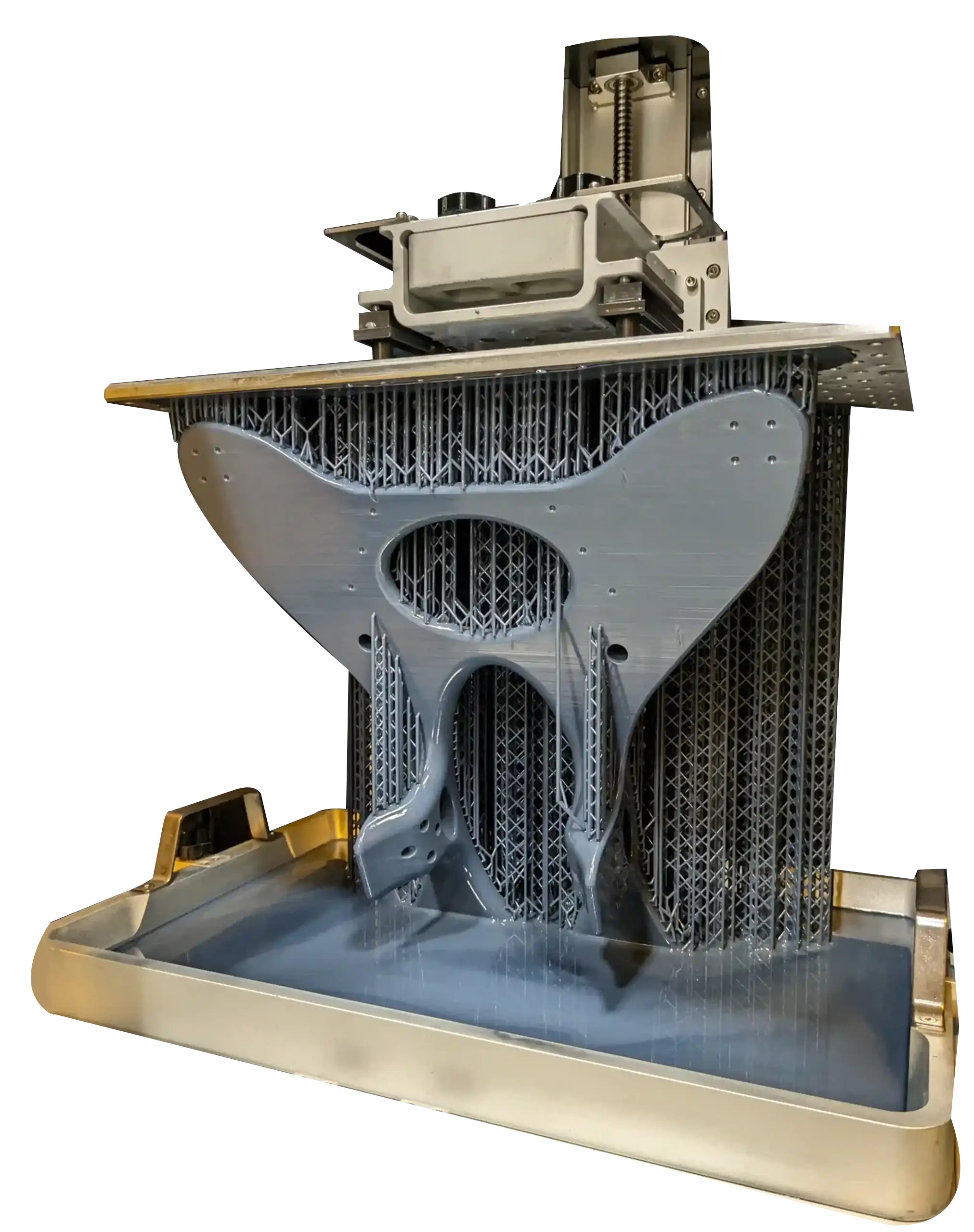

At Crenable, we’re redefining on-demand additive manufacturing by combining high-speed, large-format stereolithography additive manufacturing with an efficient, customer-first approach to production. Whether you need a single prototype or a full-scale production, we solve manufacturing challenges for businesses and individuals from all industries.

Competitor Price Analysis

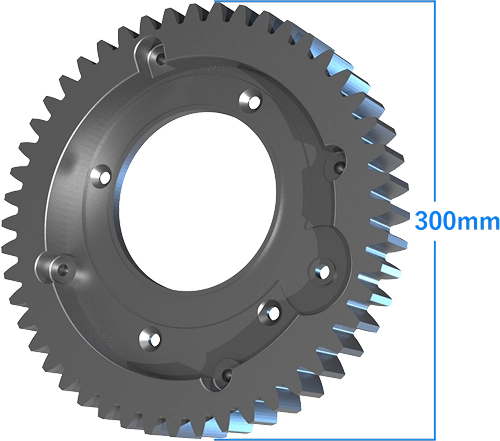

The large-scale model below was used to quote 4 different competitors providing the same prototyping service.

How We Make It Happen

At Crenable, we’ve engineered a streamlined, cost-efficient manufacturing process that enables you to access 3D printing technology at a fraction of the industry price. Our shop focusses on high-speed, large-format industrial resin 3D printing machines with custom-designed post-processing equipment.

Testimonials

Nathan was quick with his emails back, printed out the products I had sent him to print overall great doing business with him, will definitely be back if I need more stuff printed.

Great Job by Nathan at Crenable. Went over and above when making my classic car part with not only accurate dimensions but right down to the proper painted and polished finish. And at a very good price. Thanks so much. Definitely recommend crenable to everyone.

I found Crenable in a google search when looking for 3D printing for some backplates I needed to have printed for prototypes for my business. Nathan was so great to work with on this project, he is very knowledgeable, got my print done quickly and perfectly just the way I needed.

Nathan at Crenable is a very nice young chap - exceptionally knowledgeable and skilled at his craft. Had additional tips and tricks for me and even and delivered my print. Highly recommended for any 3D printing project.

Materials

Standard resin is our least expensive resin best suited to visual prototypes, art pieces, miniatures, and display models. It can be dyed in custom colors and yields great detail.

This material is reinforced with ceramic powder to give it superior mechanical strength, stiffness, and a temperature resistance of 250 degrees Celsius.

This resin is optically clear and non-yellowing, enabling you to print beautiful art pieces, breakaway glass props, or safety shielding devices where transparency is a must.

This resin is a softer, flexible plastic that has great impact resistance when printed as a thick part and great flexibility in thin sections. Model hollowing can allow for precise tuning of the flexibility/compressibility.

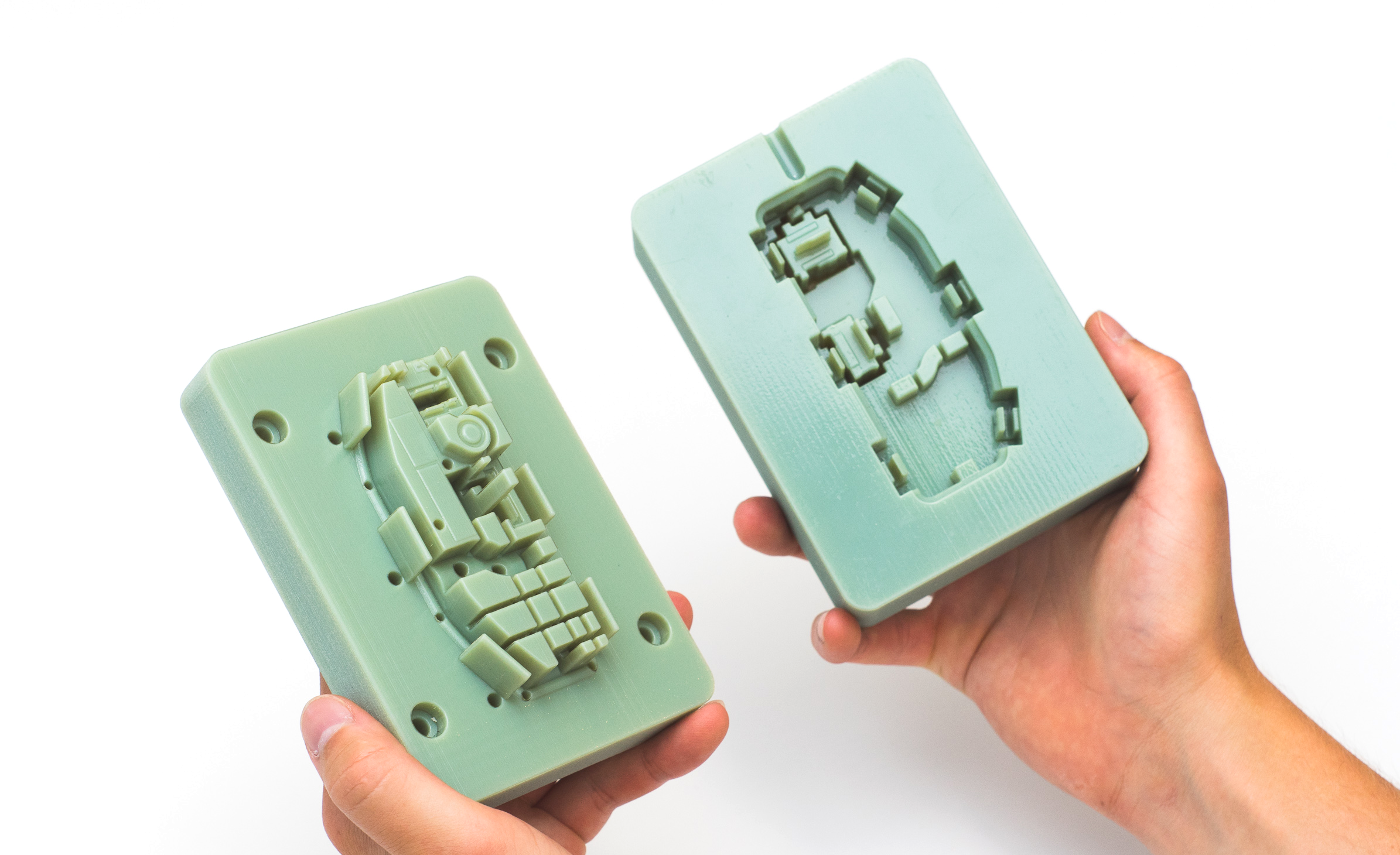

Our elastic resin has silicone-like properties, enabling you to 3D print molds that can be used immediately. It is also used in many consumer products or assembly parts.

Wax resin is suitable for applications in the dental and jewelry industry for its soft texture and medium flex characteristics. It is also used in investment casting...

Technology

Masked Stereolithography (MSLA) is an advanced form of resin-based 3D printing that utilizes a high-resolution LCD screen to cure liquid photopolymer resin layer by layer. This method is particularly powerful for large-format printing, allowing for high-precision, high-detail parts on a much larger scale compared to traditional SLA or DLP printers.

Standard

Standard

Rigid High Temp

Rigid High Temp

Flexible

Flexible

Elastic

Elastic