Technology

Masked Stereolithography (MSLA) is an advanced form of resin-based 3D printing that utilizes a high-resolution LCD screen to cure liquid photopolymer resin layer by layer. This method is particularly powerful for large-format printing, allowing for high-precision, high-detail parts on a much larger scale compared to traditional SLA or DLP printers.

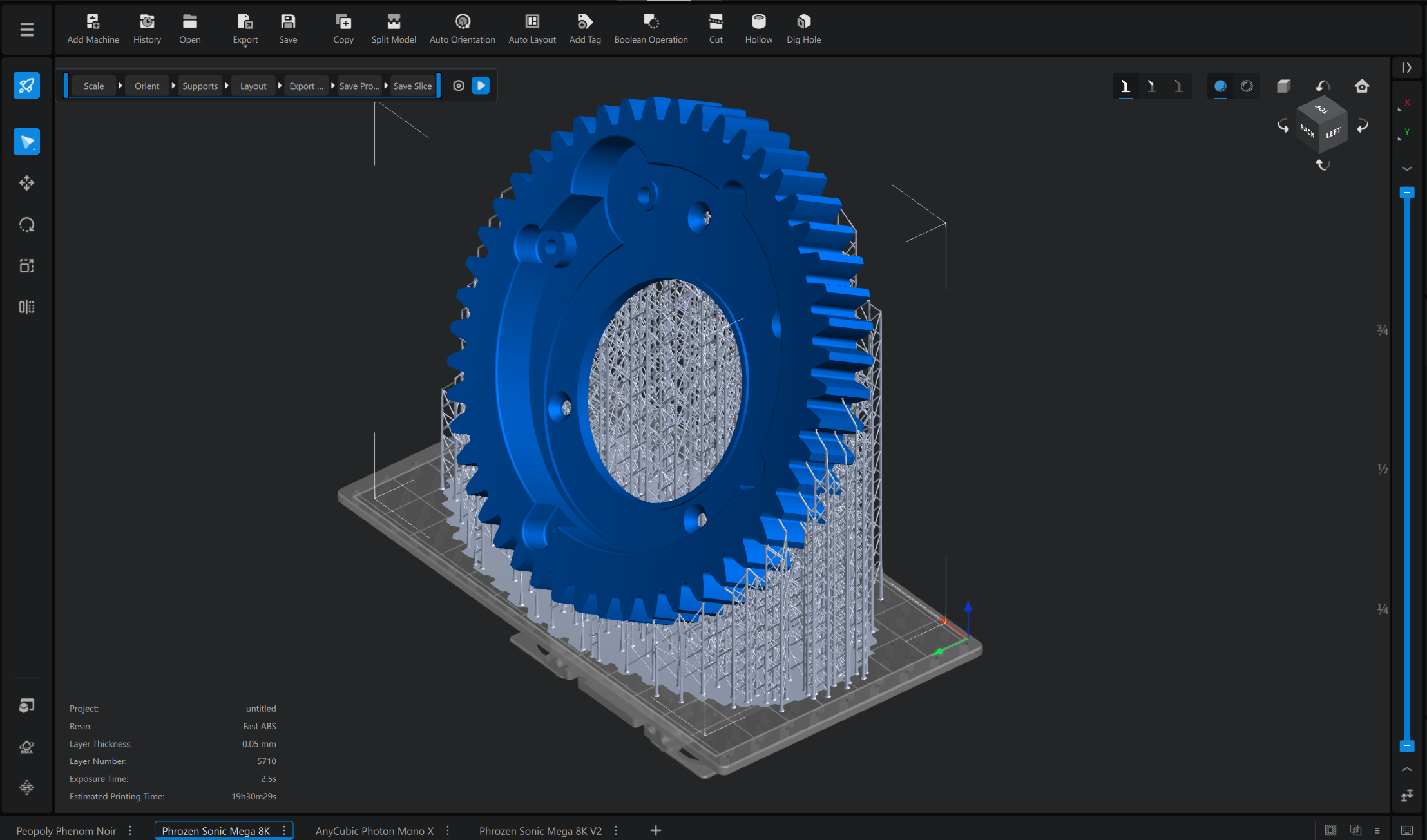

- The process starts with a 3D model created in CAD software.

- The model is then sliced into thin layers using specialized software.

- The printer translates these slices into mask images, which are displayed on an LCD panel.

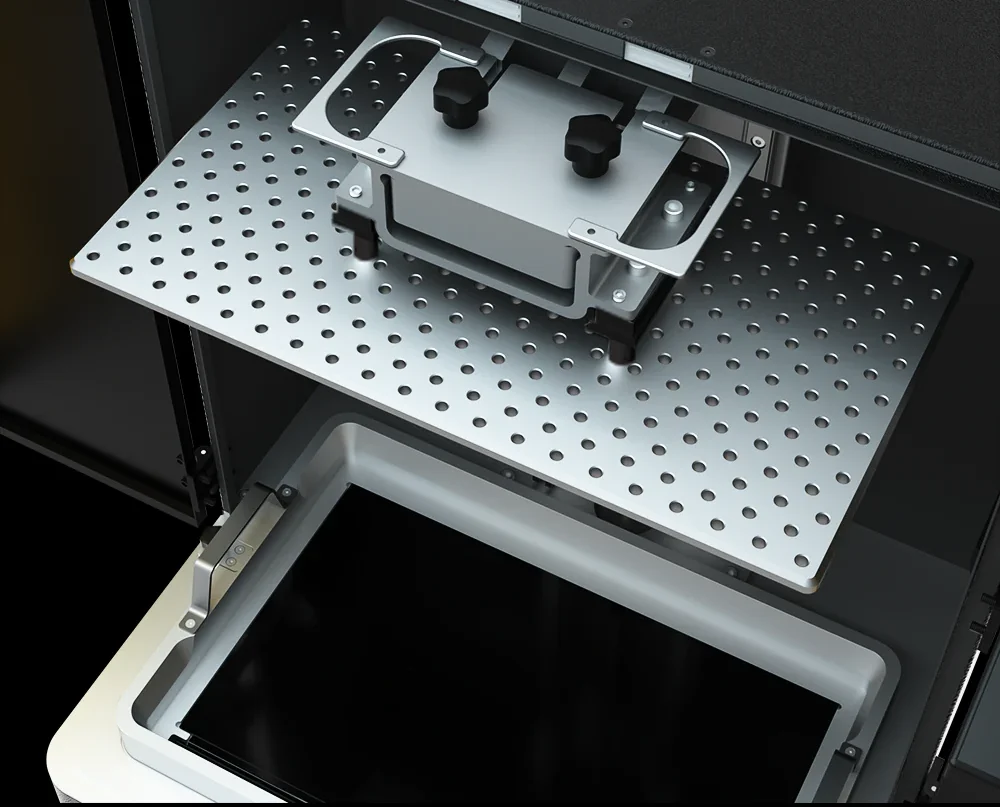

- The build plate is submerged into a vat filled with liquid photopolymer resin.

- A transparent film (FEP or PFA) at the bottom of the resin vat allows light to pass through while preventing adhesion.

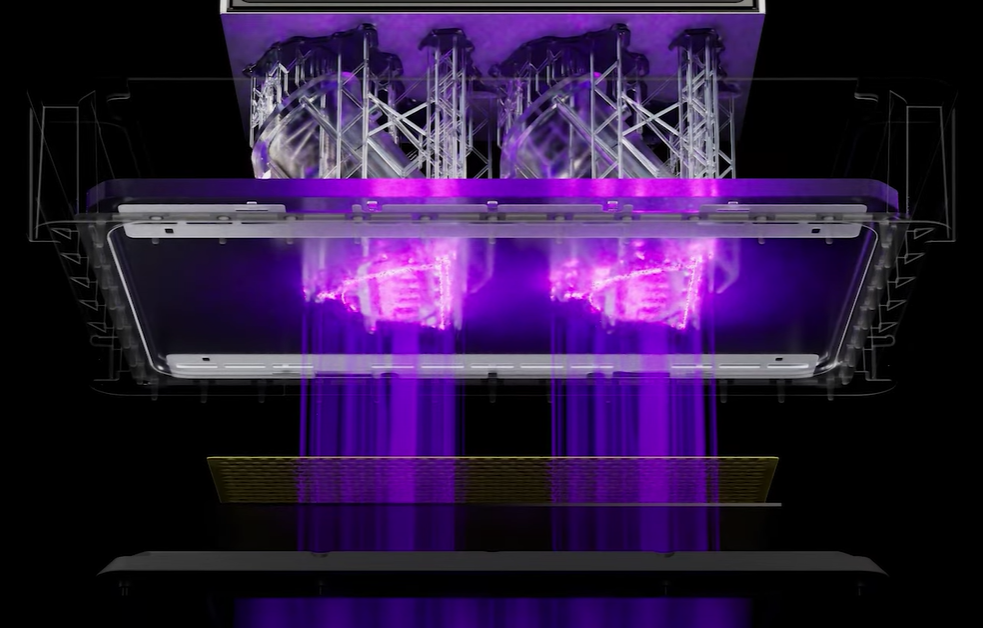

- A UV light source located beneath the LCD panel projects light upwards.

- The LCD masks specific areas, exposing only the required shape of the current layer.

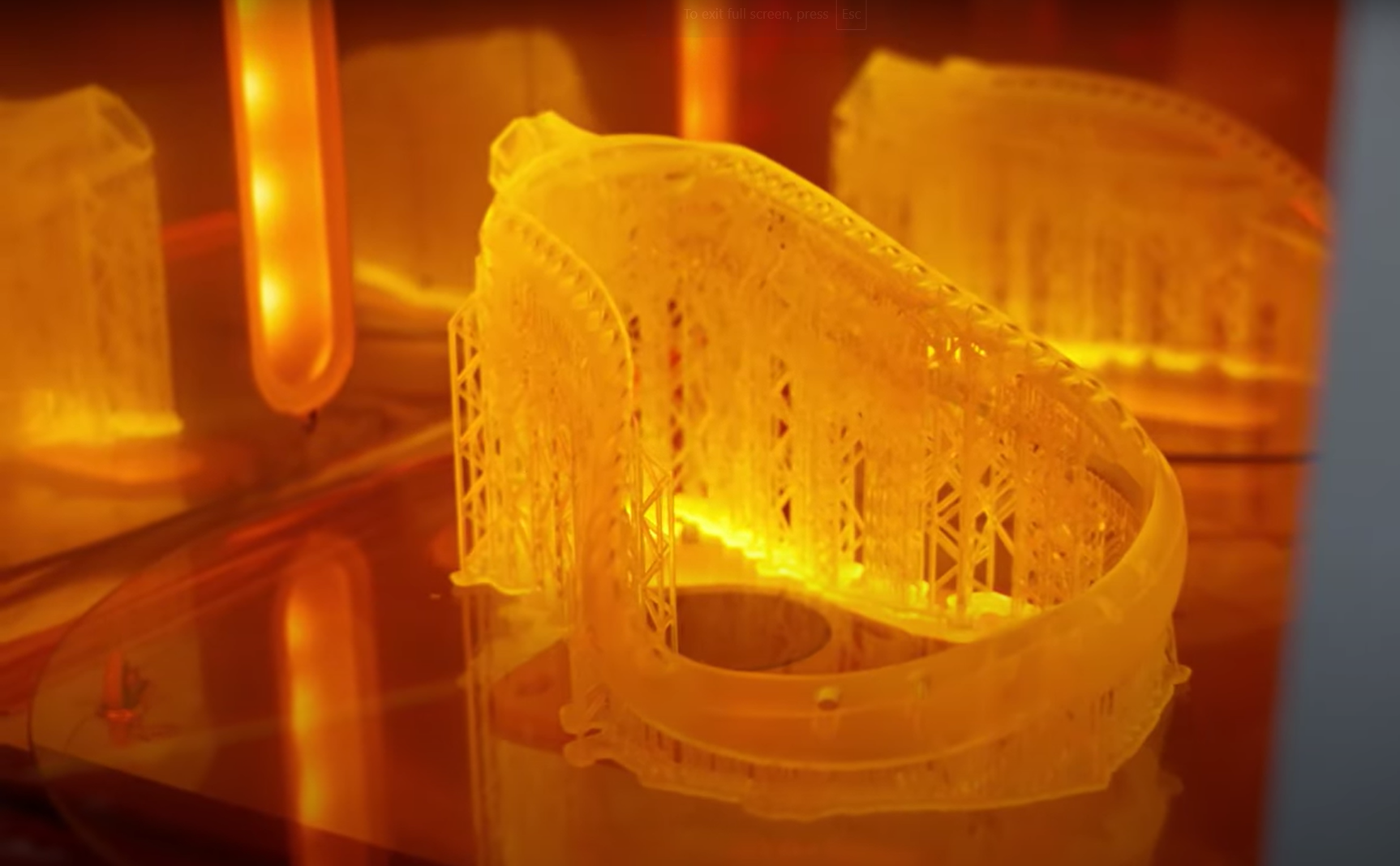

- The exposed resin cures instantly due to UV light polymerization.

- The printed parts are removed from the 3D printer and supports are removed from the parts

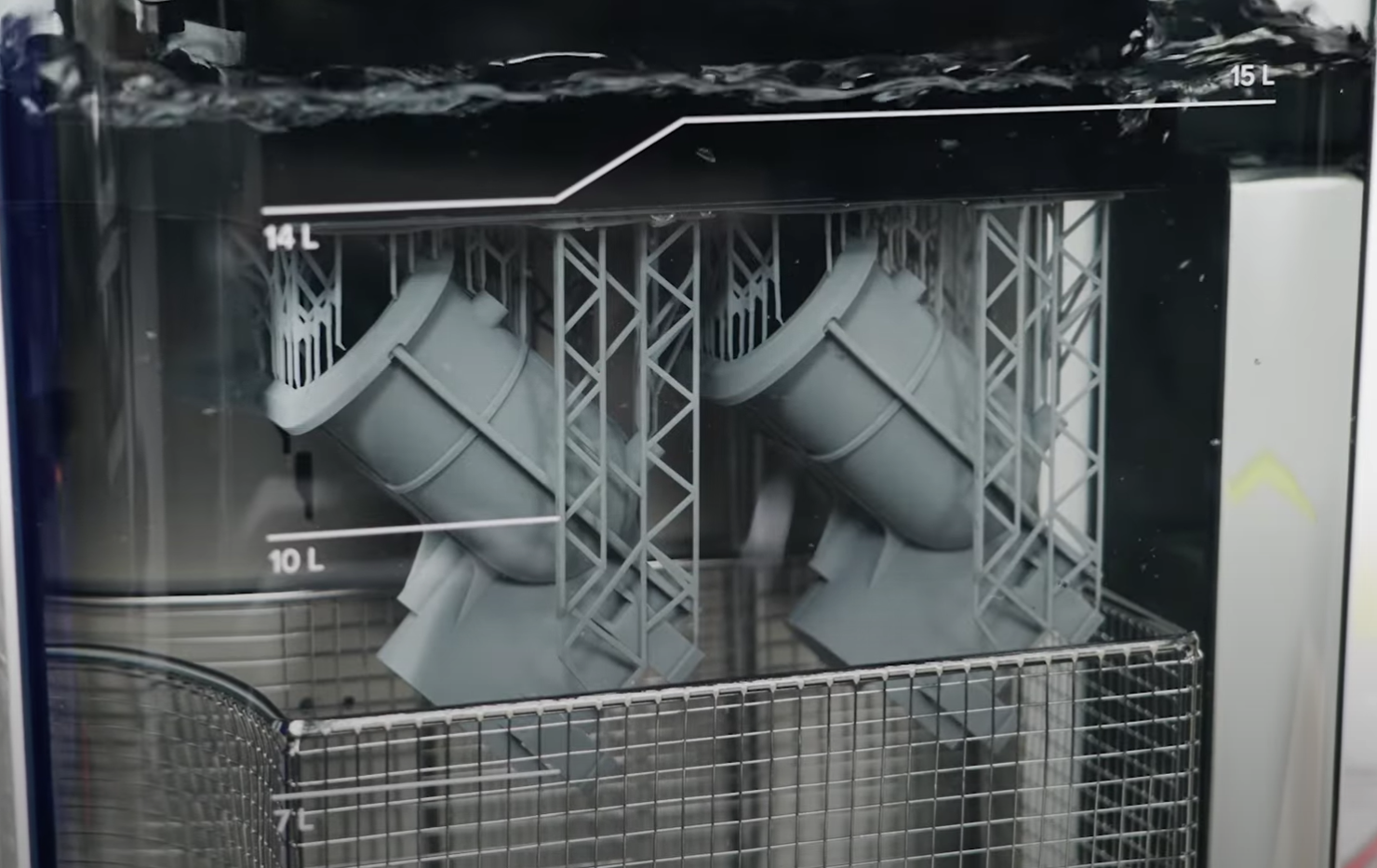

- Excess resin is washed off in an ultrasonic cleaning tank filled with 95% ethanol

- Once removed from the bath, parts are blasted with high pressure air to evaporate the solvent away from the parts until fully dried internally and externally.

The part is then placed in a heated UV-curing chamber to achieve its final mechanical properties.

Massive Build Volume

Print larger single parts or batch-produce multiple items at once.

Unparalleled Resolution

Unlike FDM, MSLA achieves ultra-fine details without visible layer lines.

Fast & Scalable Production

Entire layers cure at once, making MSLA significantly faster than laser-based SLA.

Stronger, High-Quality Materials

Supports a wide range of resins, including engineering, biocompatible, flexible, and high-temp resins.

Cost-Effective for Large Parts

Uses less material waste than CNC machining or injection molding for custom one-offs or small-batch production.